Innovation in material science has shaped the world and civilisation as we know it, from the first use of concrete-like material around 8000 years ago to the development of a new alternative material for effective thermal management in advanced wearable electronics just this year. Scientists are constantly looking for new ways to make existing materials lighter, stronger, or vastly improved in some way. In many cases, developing new materials entirely.

Although developed several decades ago, carbon fibre is an example of a material that has become increasingly important in modern engineering applications.

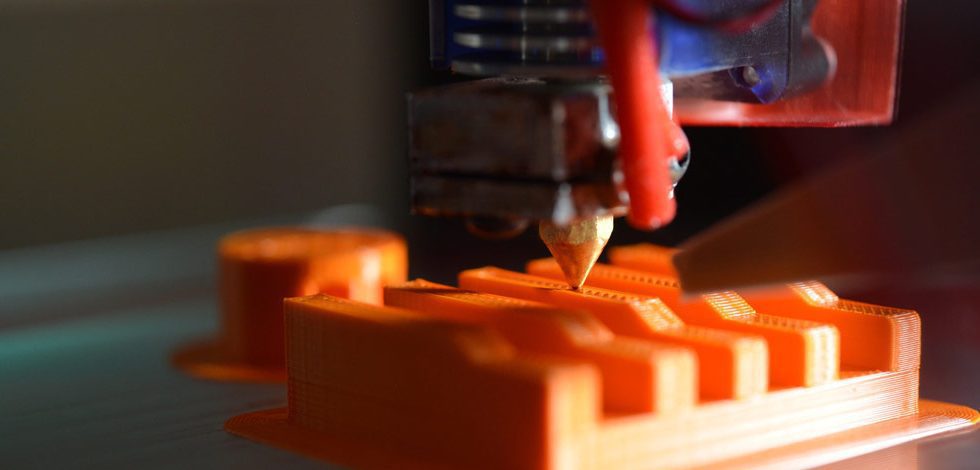

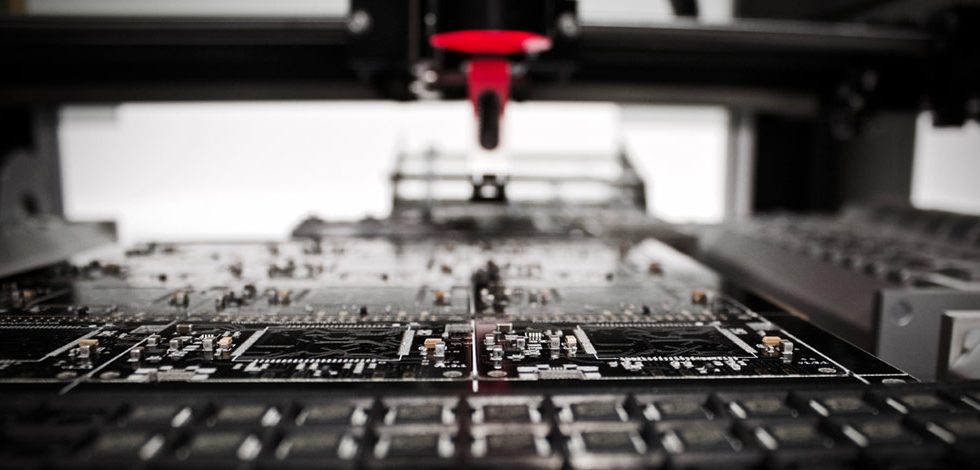

Advancements in material science have enabled the expansion of potential applications for carbon fibre and improvements in its performance. New manufacturing methods have enhanced its production, allowing more automated processes and reducing production time and costs. Although traditional carbon fibre composites have been difficult to recycle, developments are underway to address their recyclability and sustainability.

Material science innovation isn’t always successful

No material is perfect. While carbon fibre provides extraordinary tensile strength relative to its weight, the same cannot be said for its compressive strength. A poignant real-world example of this limitation unfolded in the recent incident involving the Oceangate Titan deep-sea submersible. The submersible was equipped with a hull made of carbon fibre. This material, which is highly valued in the aerospace sector for its lightweight and high tensile strength, is less commonly used in marine engineering, where high compressive forces are a concern. This is because its ability to withstand the extreme pressures found in deep-sea environments is not as well understood. During its deep-sea excursion, the submersible faced extreme compressive forces due to the immense pressure of the water at such depths. While multiple factors may have contributed to the incident, this undoubtedly played a prominent role.

We talk to many clients about how they are innovating to find ways to improve their materials. Even small changes can have a significant impact on a material’s applications. While not all research and development aimed at material improvement will be successful, innovation is still taking place. R&D tax relief schemes enable companies to pursue such innovation by offering tax refunds on eligible expenses, which can then be reinvested to enable further innovation. Contact us below to find out how Ayming can assist your business.

Speak to one of our innovation experts today!

No Comments