Here’s a question to ponder upon. Who has made the biggest difference to the lives of Londoners? Harry Beck, who first designed the tube map? Dick Whittington, the medieval merchant and Lord Mayor? Boris Johnson?

My own nominee is someone else: Sir Joseph Bazalgette, a civil engineer who served as chief engineer of the Metropolitan Board of Works.

Who was Sir Joseph Bazalgette?

Bazalgette was born on 29 March 1819, the son of a Royal Navy captain, at Hill Lodge in Enfield. Then a small, rural community, Enfield was far removed from the great metropolis of which it would soon become a part. Initially working as a railway engineer, Bazalgette joined the Commission of Sewers in 1849, and when the Metropolitan Board of Works was created to manage London’s infrastructure and government in 1856, he was immediately appointed Chief Engineer. It is in this role that he made his most significant contributions to the city.

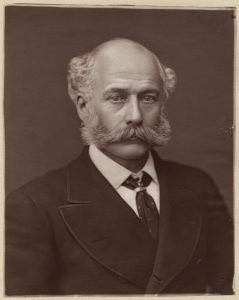

Sir Joseph William Bazalgette. Source: Lock & Whitfield 1877 [Public domain], via National Portrait Gallery

Work in the Houses of Parliament (only recently rebuilt after the 1849 fire that destroyed most of the old Palace of Westminster) was affected, and the Earl of Derby considered moving the Government out of London. Attempts to mitigate the problem by pouring lime into the rivers proved futile, and in June the Government passed the Metropolis Local Management Amendment Act. Becoming law only 18 days after being introduced (a sign of the urgency required), this placed the responsibility to clean up the Thames on the Metropolitan Board of Works. The job landed on Bazalgette’s desk.

Designing London’s first sewer

The result was one of the greatest, and most innovative, feats of Victorian engineering. Over the next seven years, Bazalgette oversaw the design and construction of a vast and complex network of interconnecting sewers, including over 100 miles of ‘interceptor sewers’, and pumping stations. These sewers were designed to channel the waste of the growing metropolis downstream to Beckton and Crossness, where it could be discharged to the Thames Estuary away from the growing metropolis.

He also built the largest sewers in an unusual shape: rather than a more conventional circular cross-section, the interceptor sewers were constructed as an oval, narrower at the bottom but widening towards the top. This combined great strength with the capacity to ensure adequate flows even at relatively low water. Building this network was a huge undertaking – over 1,100 miles of new sewers needed to be constructed, requiring the excavation of 3.5 million cubic yards of earth. 318 million bricks were laid, held in place by a million cubic yards of cement.

Material innovation

This cement itself was revolutionary: Bazalgette recognised the need for the cement to be waterproof, so he used Portland cement (still a relatively new product) instead of lime mortar. However, Portland cement required very precise mixing, and if the balance of limestone, clay, and water was not correct then the cement lost much of its strength. Bazalgette therefore refined the process for mixing the cement, and implemented a rigorous testing procedure for each batch, ensuring that the network was only built using cement that was up to the task. Lessons learned are applied to this day, and I will examine further developments in concrete being made in constructing the new sewer network.

The completion of the sewer network in 1865 achieved its goal – sewage no longer contaminated the Thames in the centre of London. Although to some extent the problem was moved downstream (a problem that challenged engineers for the next 50 years), health and conditions in central London improved dramatically. It is ironic that the health improvements were actually achieved coincidentally, since the mechanism for spread of disease was not well understood at the time. For most of the 19th century, miasma theory held primacy, based on the idea that disease was spread by noxious vapours and “bad air”.

Water contamination and disease

Germ theory, the more modern idea of diseases caused by microorganisms, was in its infancy. In fact, one of the most significant works that contributed to acceptance of the theory was contemporaneous with Bazalgette’s sewers. Dr. John Snow’s seminal investigation of the 1854 Broad Street cholera outbreak was one of the first scientific papers to attribute disease spread to water contamination (and this led scientists to investigate what might be contaminating water), but it was several decades before the theory met with serious scientific acceptance. Nevertheless, the removal of sewage from central London reduced water contamination, and as a result reduced disease, even if the mechanism was misunderstood.

Some of the significance of Bazalgette’s work can be appreciated in the life of the system he built. He recognised that London was a growing city (between his birth and the sewer works, the population had more than doubled), and expected this to continue. He therefore ensured that the capacity of the system was vastly in excess of the expected need, building larger diameter sewers than even the most extreme forecasts of volume required. The foresight thus shown continues to pay dividends to this day, since the network built in the 1860s still serves the city 150 years later, with the population four times that of Bazalgette’s day.

A modern sewer for a growing city

Now, however, the network is starting to creak, and as a result London is embarking on another enormous infrastructure project to enhance its sewers for the 21st century. The Thames Tideway, also known as the supersewer, is a 25km long tunnel being constructed between 30 and 60 metres below the Thames, linking Acton in the west to Beckton Sewage Treatment Works to the east of London. The objective is very similar to Bazalgette’s interceptor sewers – to channel sewage and wastewater from the multitude of collector sewers away from the centre, and to avoid discharging untreated sewage into the Thames.

Despite being similar in concept to Bazalgette’s system, the Tideway is presenting today’s engineers with new challenges. Building a tunnel of this scale, at this depth, through the congestion of subterranean London is no easy task. Already, even though the project is still at an early stage, innovative new techniques are being developed to facilitate the construction.

Some examples that our clients have worked on include:

- The routing of the tunnel itself. Subterranean London is an increasingly confusing mess of tunnels (most notably the Underground), service infrastructure, basements, and deep piled foundations. In addition to avoiding direct conflict, the Tideway must also avoid causing changes to ground conditions that would compromise the integrity of the other systems. As a result, the route of the Tideway is largely following the route of the Thames itself, where infrastructure is less congested, and at a deeper level than most existing structures. This, however, presents further challenges for the engineers, due to the difficulties in tunnelling at this depth.

- New types of waterproof concrete are being developed, suitable for jointing between tunnel sections and application by spray-concreting techniques. Previously, the additives required to make concrete waterproof, and for spray-application, have been incompatible, which has limited the techniques for constructing tunnels such that waterproof membranes had to be incorporated if the inner lining of tunnels was to be spray concreted. Given the scale of the Tideway, however, the economy of spray concrete was significant, so the investment has been made to find a suitable mixture of additives which offers both features.

- A new method for installing primary lining sections, without the use of temporary securing bolts. Modern tunnels are lined using precast concrete segments (a substantial development from Bazalgette’s bricks), but these segments are usually fixed in place using temporary retaining bolts until the ground is stable. Such a process is time-consuming and weakens the waterproofing of the finished tunnel, so the contractors are creating an improved process using plastic dowels to interlock the segments. This is simpler to install, and does not introduce the same water ingress potential. It does, however, create a difficulty with regard to both the structural strength of the tunnel (until ground stabilisation is complete) and maintaining the correct tunnel shape during construction.

- Expansive polymers are being used for ground stabilisation in London Clay. Expansive polymers are relatively new to ground stabilisation, and usually used at relatively shallow depths in surface soils. They have never before been used at depth, in the complex geotechnics of London Clay. Experimentation is ongoing to explore the use of the polymers in place of a more conventional cementitious grout, on the basis that the technology could be used to provide a more ‘real-time’ approach to ground stabilisation.

Since tunnel boring is only commencing in early 2019, much of this development is still ongoing. There is no doubt that, over the remainder of the construction of the Tideway, the engineers will continue to face challenges, and to develop new engineering solutions to overcome them.

The legacy of Bazalgette lives on, in the innovation required to manage a problem today that would have been very familiar to him 150 years ago. Perhaps one of the most significant tributes to this legacy lies in the name of the company constructing the Tideway: Bazalgette Tunnel Ltd.

No Comments